Health Inspection of Spring Hangers & Pipe Supports

Keeping your piping systems safe, reliable, and stress-free.

Spring hangers and pipe supports are critical for the smooth operation of any plant. Over time, they can shift, corrode, seize up, or simply go out of calibration. If left unchecked, these small issues can turn into big problems—like overstressed piping, equipment damage, or even unexpected shutdowns.

That’s why AAA Supports Pvt Ltd offers on-site health inspection services for installed spring hangers and supports. Our team helps you identify problems early, restore proper settings, and keep your plant running safely and efficiently.

Why Regular Inspections Matter

- Safety first – Faulty supports can overload piping and nozzles, leading to serious risks.

- Extend equipment life – Healthy supports reduce vibration and stress on pumps, turbines, and vessels.

- Stay compliant – Our checks follow ASME, API, and IBR guidelines.

What Our Inspection Covers

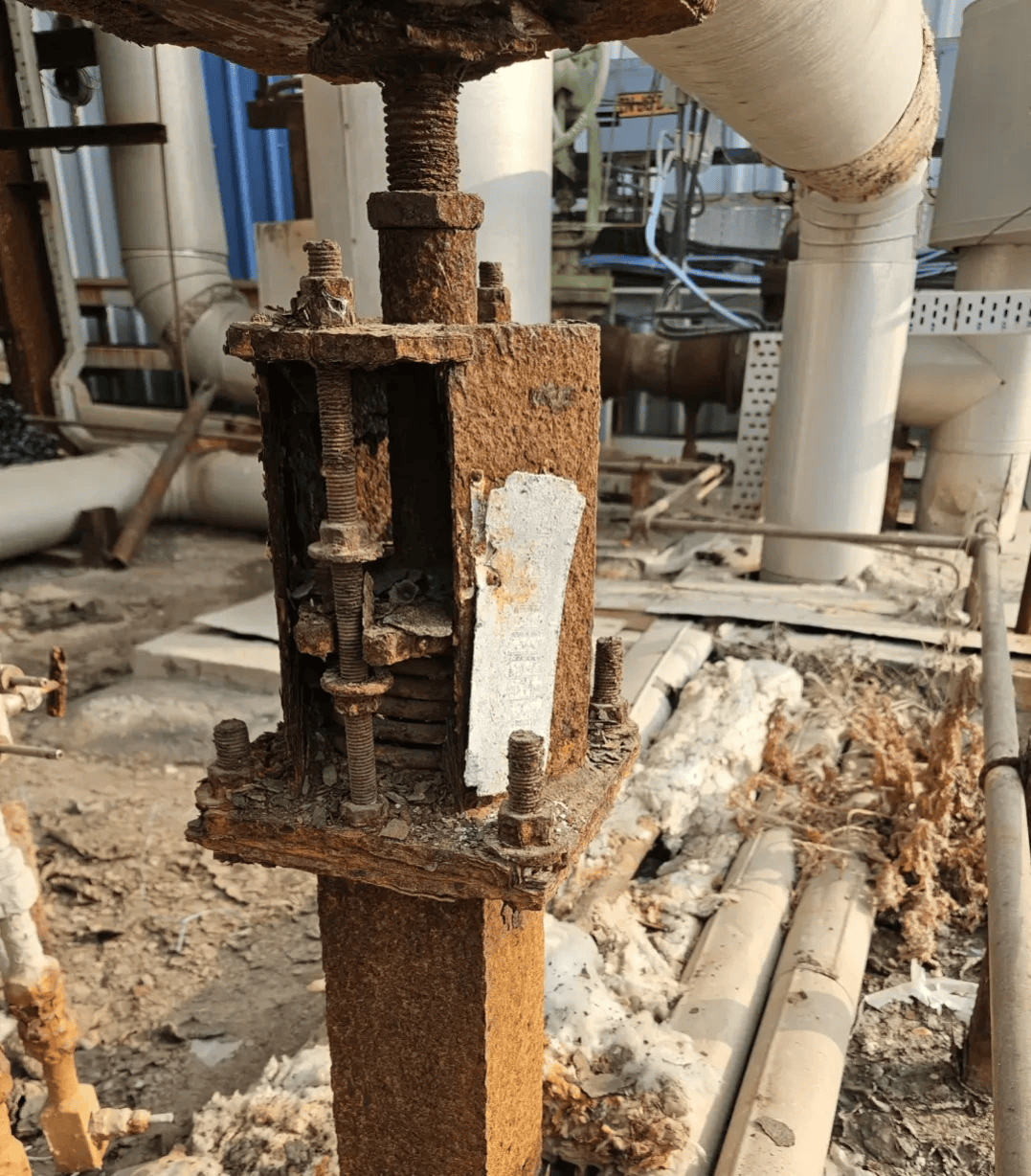

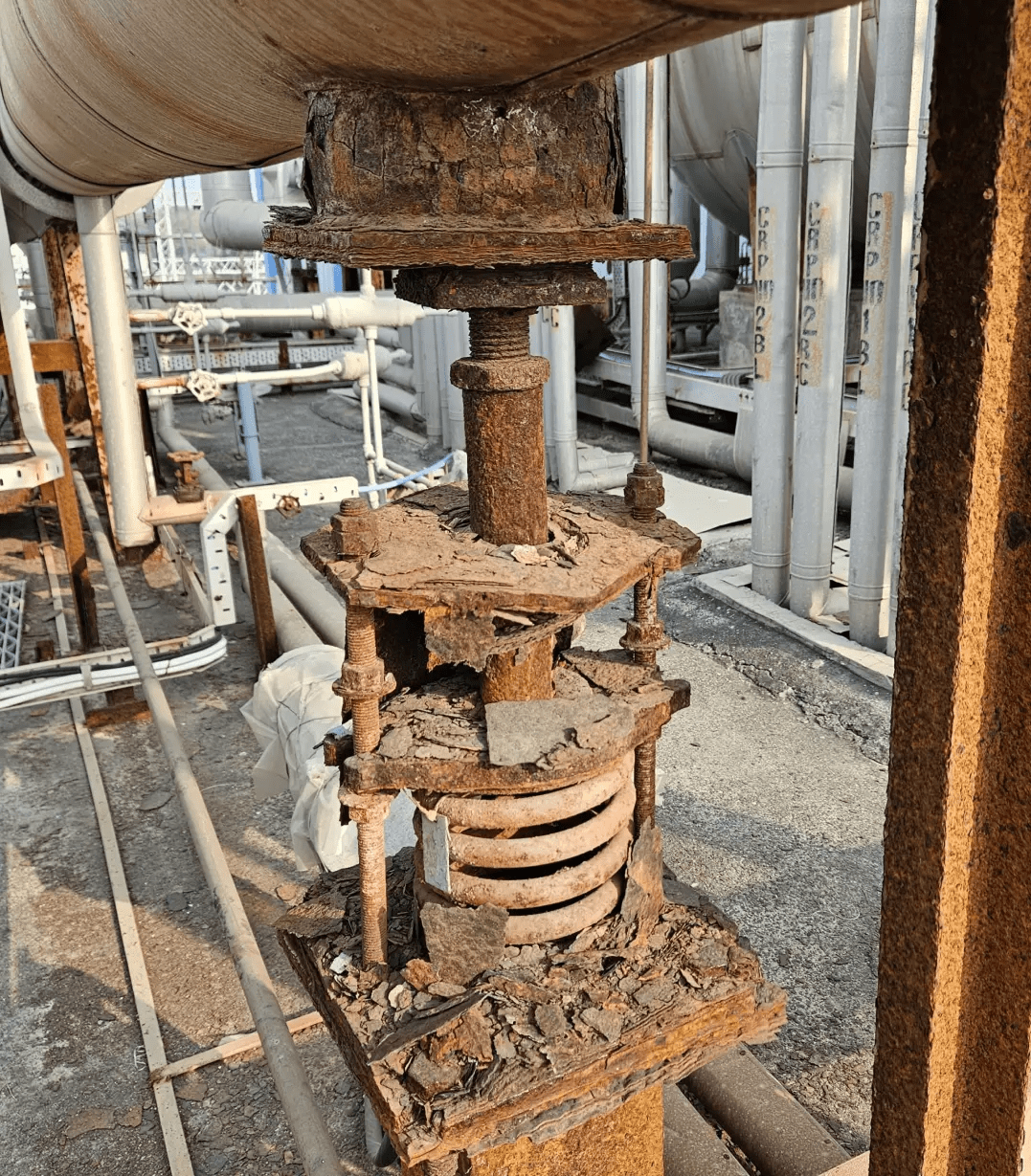

- Visual checks – spotting corrosion, cracks, missing bolts, or stuck springs.

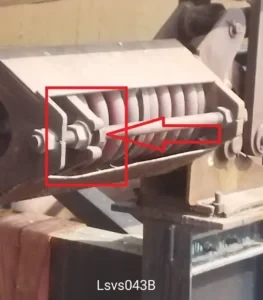

- Travel & load verification – making sure the spring is carrying the right load and moving freely.

- Hot & cold setting checks – comparing actual field settings with design values.

- Functional testing – ensuring snubbers, rigid struts, and other restraints work properly.

- Reporting & recommendations – a clear summary of what’s fine, what needs adjustment, and what should be replaced.

What We Typically Find

- Springs locked in the wrong position after maintenance.

- Supports jammed due to rust or dirt.

- Incorrect load distribution causing extra stress on equipment nozzles.

- Snubbers not activating when they should.

- Travel indicators that no longer show the right readings.

What You Get From Us

- Detailed inspection report – with photos and measurements.

- Tagged list of supports: – OK, Needs Adjustment, or Replacement.

- Action plan – so you know exactly what to fix first.

- Updated datasheets – with verified load and travel values.

How We Work

- Review design data – spring charts, settings, drawings.

- On-site inspection – check each support visually and physically.

- Adjustments – small corrections are done right there, where possible.

- Analysis – compare field readings with design intent.

- Final report – with clear recommendations and next steps.

Industries We Support

- Power plants (thermal, nuclear, HRSG, CCPP)

- Refineries & petrochemical complexes

- Fertilizers & chemicals

- Water & desalination projects

- Pharma & food processing plants

Why Work With AAA Supports?

- Our engineers are specialists in spring hanger design and troubleshooting.

- We know the equipment inside-out (we design and supply them too).

- Many inspections can be done while your plant is still running.

- We don’t just inspect—we help you fix, recalibrate, or replace as needed.

Ready to Schedule an Inspection?

- Let’s make sure your supports are doing their job.

- Email: sales@aaasupports.com

- Phone: +91-8851882754

- Website: www.aaasupports.com

✨AAA Supports Pvt Ltd – Supports Systems, You Can Trust.