Constant Spring Hanger & Supports

Constant spring support is specially used to accommodate constant effort load, excessive movement of the pipeline due to high temperature and pressure of thermal movement. Constant load takes place through its range by a perfect counter balance crank lever where load and spring movements through the pivot ensure the minimum kinetic variation.

Constant Spring Hangers & Supports we offered with

- Ancillary Equipment

- Beam Brecket

- Turn Buckle

- Hanger Rod

- Pipe Clamp

- Riser Clamp

- U-Clamp

- Eye Nut

- Roller, Anchor & Slider (Ptfe/Graphite/Ball)

Range

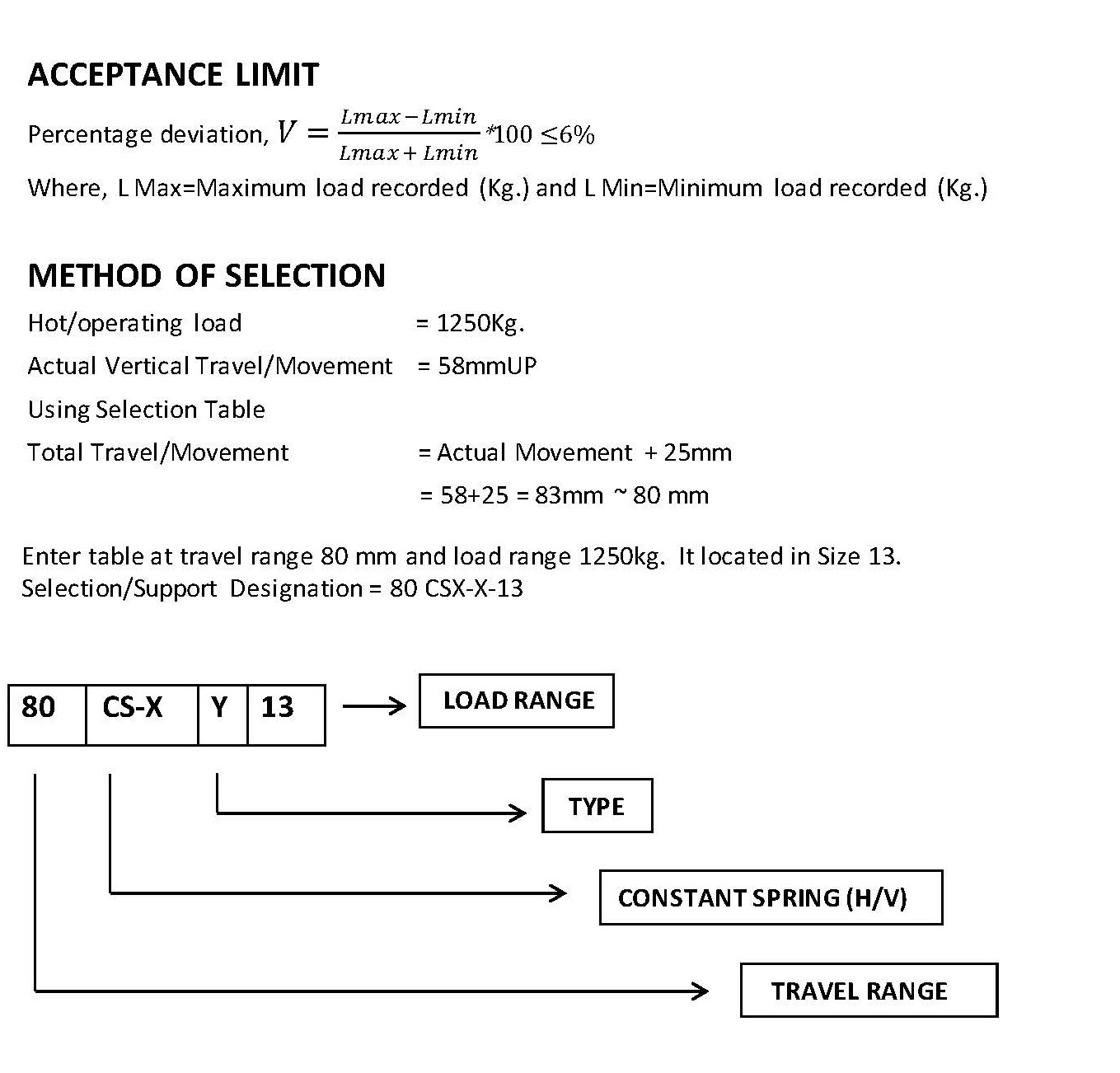

We offer twenty size of group A to G with product range from CS-1 to CS-5 for both horizontal and vertical model. Twenty size Constant spring supports allows aload range from 10kg. to 23 tons and maintains the travel range from 40mm- 420mm.

Material

|

SPRING |

EN-42 or IS-4454 Part-1 Gr-II upto Ø12mm & EN-45/EN-47-ABOVE Ø12mm. |

|

CASING |

IS-1239/3589(medium) & IS-2062 |

|

HANGER ROD |

Carbon steel to IS-2062 Gr A/B |

|

TOP LUG |

Carbon steel to IS-2062 Gr A/B |

|

BEAM ATTACHMENT |

Carbon steel to IS-2062 Gr A/B |

|

TURN BUCKLE |

Carbon steel to IS-1875 Gr CL-2(Forged) upto M30 |

|

PIPE TB (SA 106 Gr B) |

Carbon steel to IS-2062 Gr A/B (Machined) above M30 |

|

PIPE CLAMP, SHOE & U-BOLT |

Carbon steel to IS-2062 Gr A/B upto Temperature 350°C |

|

|

Alloy steel to 1%Cr., 0.5%Mo (ASTM A182 F11) upto Temperature 470°C |

|

|

Alloy steel to 2%Cr., 1%Mo (ASTM A182 F22) upto Temperature 550°C |

|

|

Stainless steel to AISI 304/316/321 above temperature 550°C |

|

BOLT /STUD & NUT |

Carbon steel to IS-1363/67 CL-4.6/4.0 upto Temperature 340°C |

|

|

Alloy steel to A193 Gr.B7/A194Gr.2H upto Temperature 470°C |

|

|

Alloy steel to A193 B16/A194 Gr.4 upto Temperature 550°C |

|

|

Stainless steel to A193 B8/A194 Gr.8 above Temperature 550°C |

|

PLATE/ST.STEEL |

Carbon steel to IS-2062 Gr A/B |

|

LOW FRICTION PAD |

PTFE upto Temperature 210°C |

|

|

Graphite upto Temperature 550°C |

|

STEEL BALL |

Carbon steel upto Temperature 350°C |

|

|

Stainless steel upto Temperature 550°C |

|

NAME PLATE & LOAD-TRAVEL SCALE |

Aluminum Anodized |

|

PAINTING |

|

|

Our Standard |

Two Coats Of Zinc Chromate Red/Grey oxide primer IS:2074 and one coat Of Finish enamel paint to IS-5:1973 |

|

On Request |

Spring to be PU / Neo-prene rubber coating. |

|

Casing & component to be hot dip galvanized to IS: 2629/A153/A123 except threaded portion. |

|

|

Epoxy zinc phosphate primer & high build epoxy finish. |

|

|

Threaded component shell be electro zinc coated to ASTM B633/B76 |

|

|

MARKING |

Each and every variable & constant supports are fitted with a metallic load travel scale cum name plate on which all references are punched Such as Cold & Hot Load, Travel, Support Tag Number, Size etc. All items of ancillary equipment are clearly identified with Clint's tag number. |

|

PACKING |

Each and every spring support and its ancillary equipment are properly packed in Wooden Box/Crate. Packing list shall indicate contain of item against respective box no. |

Guarantee

Each and spring support /hanger assembly is guaranteed for a period of 18 month from the date of supply or 12 months from the date of commissioning, whichever is earlier. We shall replace with free of charges if any materials, which owing to defect in raw materials or workmanship, should fail within guaranteed period.